Essential Food Safety: Protecting Cooked Food and Proper Glove Practices in Food Handling

Introduction

In the food service industry, ensuring food safety is critical for protecting public health and maintaining customer trust. Once food is cooked, it becomes especially susceptible to contamination from improper handling, equipment, or environmental exposure. In addition, the correct use of disposable gloves is a cornerstone of food safety, but improper glove use can actually increase the risk of cross-contamination. This comprehensive guide will walk you through the best practices for protecting cooked food from contamination, the requirements for changing gloves, and the safety profile of nitrile gloves in food handling.

Protecting Cooked Food from Contamination

After food is cooked, it is highly vulnerable to contamination from hands, surfaces, utensils, and airborne sources. Preventing contamination at this stage is essential, as reheating may not always occur before consumption.

Best Practices for Protecting Cooked Food

To protect cooked food from contamination, food workers should:

- Use clean utensils and equipment: Always handle cooked food with utensils that have not come into contact with raw products. For example, use separate tongs or spatulas for cooked meats and raw ingredients to prevent cross-contamination. If a utensil was used for raw food, it must be thoroughly cleaned and sanitized before being used for cooked food.

- Practice strict hand hygiene: Wash hands thoroughly with soap and water before handling cooked food, after handling raw ingredients, and after touching any potentially contaminated surface. Even when wearing gloves, hands should be washed before putting on a fresh pair.

- Use gloves correctly: Gloves should be worn when handling ready-to-eat or cooked foods, but they must be changed at the appropriate times (detailed in the next section). Never use the same gloves for raw and cooked foods.

- Minimize direct contact: Whenever possible, avoid touching cooked food directly. Use utensils, deli tissue, or food-safe barriers to prevent hand contact with food.

- Maintain clean preparation areas: Prepare cooked food in areas that are free from raw ingredients, equipment, and debris. Sanitize counters and cutting boards regularly, especially after preparing raw foods.

- Cover and store food properly: After cooking, promptly transfer food to clean, covered containers. Store food at safe temperatures and keep it covered until served to prevent exposure to airborne contaminants.

For more detailed protocols and recommendations, you can refer to state or local health department guidelines, or consult resources provided by the U.S. Food and Drug Administration (FDA).

Source: digicomply.com

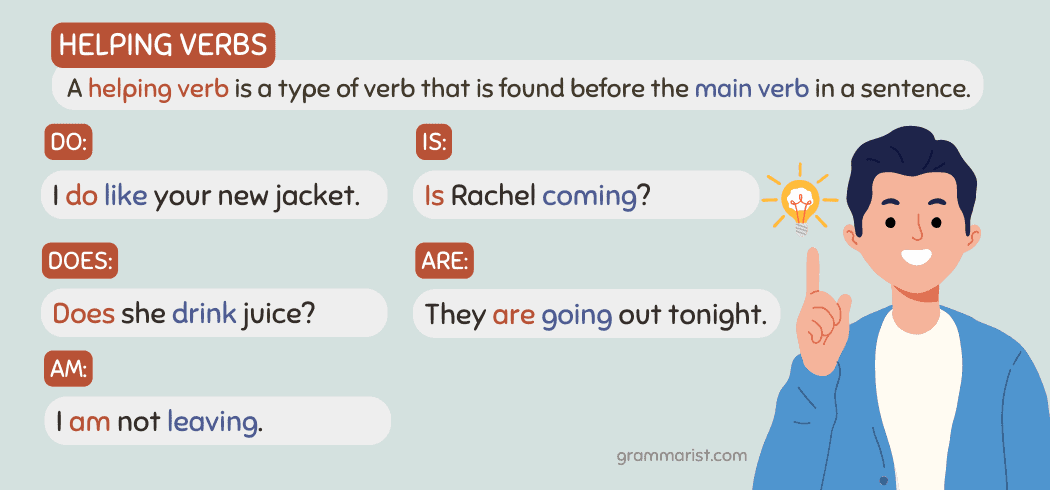

When Are Food Workers Required to Change Gloves?

Glove use is only effective if gloves are changed at the right times. Overuse or improper changing can lead to dangerous contamination. Multiple authoritative sources agree on the following requirements for glove changing in food service:

Key Moments for Changing Gloves

- Between tasks or interruptions: Food workers must change gloves whenever switching from one task to another, especially when moving from handling raw meats to cooked or ready-to-eat foods. Interruptions (such as answering the phone or handling money) also require a glove change [1] .

- After handling raw foods: Gloves that have contacted raw meat, poultry, or seafood must be removed and replaced before touching cooked or ready-to-eat foods [5] .

- Every 2 to 4 hours during continuous use: Even if gloves appear clean and intact, they must be changed at least every 4 hours during continuous use, as bacteria can multiply to unsafe levels inside gloves over time [3] . Some guidelines recommend a change every 2 hours for added safety, especially in high-volume or high-risk environments [2] , [4] .

- When gloves are damaged or contaminated: If gloves are torn, punctured, or visibly soiled, they must be removed immediately and replaced. If a worker touches their face, hair, or a potentially contaminated surface (like a trash can), they should also change gloves [1] .

- If you suspect contamination: When in doubt about glove cleanliness, it is always safer to change them. Gloves should never be washed or reused for food handling [2] .

Implementation Steps

To ensure proper glove use:

- Train all staff on when and how to change gloves, emphasizing the risks of cross-contamination.

- Provide ample supplies of disposable gloves in appropriate sizes and materials.

- Encourage a culture of safety-staff should feel empowered to change gloves whenever necessary, without hesitation.

- Supervisors should monitor compliance and provide immediate feedback if improper glove use is observed.

Examples and Scenarios

Consider a line cook preparing both raw chicken and cooked vegetables. The cook must change gloves (and wash hands) after handling raw chicken before touching the cooked vegetables. If the cook answers the phone or wipes their face, they must also change gloves before resuming food preparation. In a deli setting, a worker slicing cooked turkey should change gloves before preparing a salad for a customer to avoid transferring allergens or pathogens.

Source: cfs.gov.hk

Challenges and Solutions

One challenge is that busy environments can cause staff to forget or rush through glove changes. Posting visual reminders in prep areas and scheduling regular refresher training can help. Another challenge is ensuring sufficient glove supply; managers should regularly check inventory to prevent shortages that could lead to improper glove reuse.

Are Nitrile Gloves Food Safe?

Nitrile gloves are widely used in the food industry due to their superior strength, chemical resistance, and allergy-friendly properties compared to latex. Regulatory agencies, including the U.S. Food and Drug Administration (FDA), consider disposable nitrile gloves food safe when manufactured for food contact and used according to guidelines .

Key Benefits of Nitrile Gloves

- Latex-free and hypoallergenic: Nitrile gloves are ideal for workers or customers with latex allergies, minimizing the risk of allergic reactions.

- Durability: Nitrile is more resistant to punctures, tears, and chemicals than vinyl or latex, making it suitable for handling both wet and oily foods.

- Compliance with regulations: Food-grade nitrile gloves are designed and manufactured to meet FDA standards for food contact. Always check product labeling to verify compliance.

How to Choose Safe Nitrile Gloves

To ensure safety, food businesses should:

- Select gloves labeled as “food safe” or “food contact approved.”

- Purchase from reputable suppliers with documented compliance to FDA or equivalent standards.

- Avoid gloves with added fragrances, powders, or colorants not intended for food service.

- Store gloves in a clean, dry area away from chemicals or contaminants.

Alternatives and Considerations

While nitrile is preferred for many applications, vinyl or polyethylene gloves may be suitable for low-risk tasks. Latex gloves can be used if no one involved has a latex allergy, but their use is becoming less common in food service. Always match the glove material to the task and risk level.

Accessing Food-Safe Nitrile Gloves

To purchase food-safe nitrile gloves, food businesses can:

- Contact local restaurant supply stores and request documentation of FDA compliance.

- Order from national distributors specializing in foodservice products. Always request product safety data sheets (SDS) and compliance certificates.

- If unsure about a product’s safety, consult the FDA website or reach out to your local health department for guidance on approved glove types.

Summary and Key Takeaways

Protecting cooked food from contamination requires diligent hand hygiene, correct glove use, and strict adherence to safety protocols. Gloves must be changed:

- After handling raw foods

- When changing tasks or after interruptions

- At least every 2 to 4 hours during continuous use

- Whenever damaged or contaminated

Nitrile gloves are considered safe for food handling when labeled for food contact and sourced from reputable suppliers. For further information, food workers and managers can refer to FDA guidelines or consult their local health authority for region-specific regulations and training resources.

References

- [1] Trust20 (2025). Food Safety Best Practices: When Do I Need to Change My Gloves?

- [2] FoodDocs (2024). When Are Food Workers Required to Wear Gloves?

- [3] INTCO Glove (2025). The Proper Use and Replacement of Food Prep Gloves

- [4] WellBefore (2022). When are Food Workers Required to Change Gloves?

- [5] National Restaurant Association (2021). Get a Handle on Disposable Gloves

- U.S. FDA (2022). Glove Use in Food Service

MORE FROM eboxgo.com