Comprehensive Strategies for Food Workers to Prevent Chemical and Physical Hazards in Food

Introduction

Ensuring food safety is a top priority in every food service environment. Food workers play a critical role in preventing both chemical and physical hazards from contaminating food. Chemical hazards can include cleaning agents, pesticides, or food additives, while physical hazards range from metal fragments to personal items like jewelry. This article provides detailed, actionable guidance for food workers to effectively prevent these hazards, protect consumers, and comply with regulatory standards.

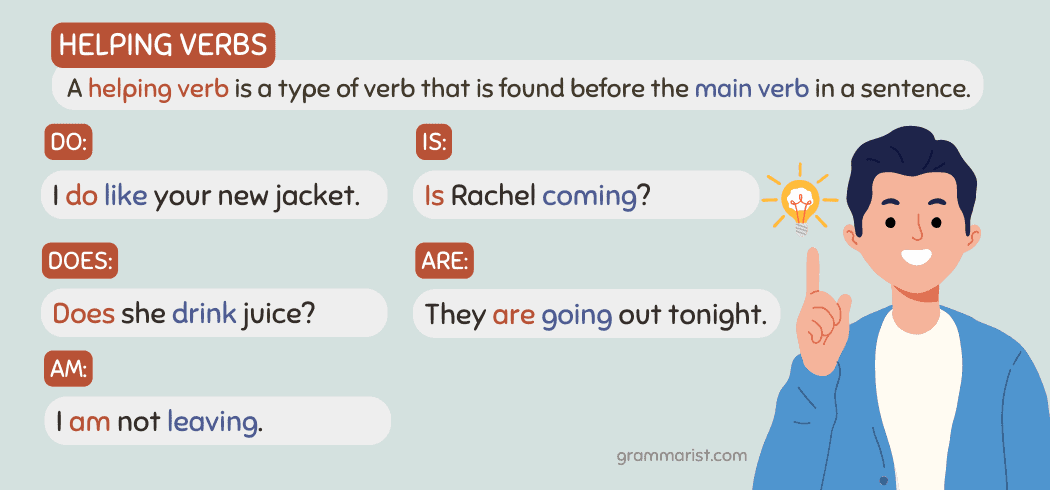

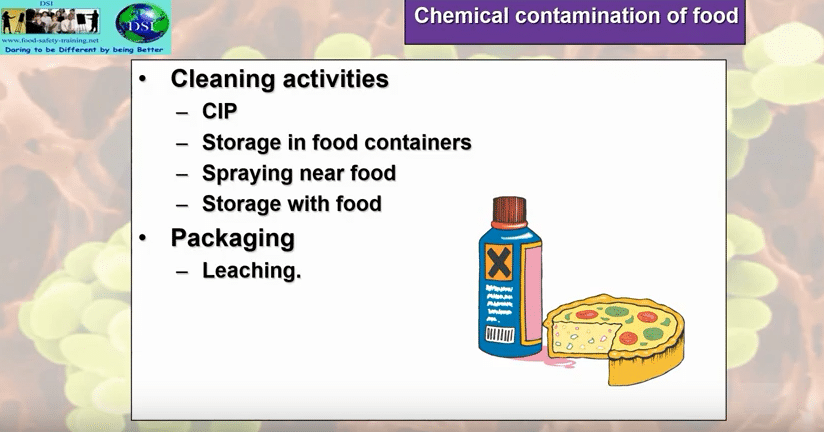

Understanding Chemical Hazards and Their Risks

Chemical hazards are non-biological substances that can enter food during processing, storage, or preparation. They may originate from cleaning products, pesticides, food additives, or even from equipment and packaging materials. Exposure to chemical hazards can cause serious health effects, including poisoning, allergic reactions, or chronic illnesses. Recognizing the sources and understanding the risks is the first step toward prevention [5] .

Key Practices for Preventing Chemical Hazards

1. Proper Storage and Labeling of Chemicals

All chemicals, including cleaning agents and pesticides, should be stored away from food preparation and storage areas. Each container must be clearly labeled with its contents and hazard information. Never store chemicals in food containers, and always use original packaging to avoid confusion. This separation prevents accidental contamination and ensures safe handling [5] .

2. Safe Use of Cleaning Agents and Sanitizers

When cleaning food contact surfaces, food workers must strictly follow the manufacturer’s instructions for dilution and use of cleaning agents. It is essential to rinse and dry surfaces thoroughly before preparing or storing food. Residues from improperly rinsed chemicals can transfer into food and pose health risks. Workers should always wear appropriate personal protective equipment (PPE) such as gloves and aprons when handling chemicals [2] .

3. Preventing Cross-Contamination

To avoid cross-contamination, never use the same utensils, equipment, or towels for both food and chemical cleaning. Designate separate tools for food handling and cleaning tasks. Food workers must wash their hands thoroughly after handling chemicals and before touching food or food contact surfaces. Good personal hygiene is crucial for minimizing the risk of chemical residues transferring to food [5] .

Source: transtutors.com

4. Responding to Chemical Hazards

If a chemical spill or contamination is detected, food workers should:

- Identify the source and the nature of the hazard.

- Isolate and remove the contaminated product from further processing or distribution.

- Report the incident to supervisors and relevant authorities as required.

- Document the incident, including corrective actions taken.

- Dispose of contaminated food according to local regulations.

Continuous improvement through regular risk assessments and updating food safety protocols helps prevent recurrence [4] .

Preventing Physical Hazards in Food

Physical hazards refer to objects that can inadvertently find their way into food, leading to injury or choking. Examples include metal shavings, glass, plastic fragments, hair, jewelry, or even pieces of equipment. These hazards can occur at any point in the food supply chain, making vigilance at every stage essential [1] .

1. Maintaining Good Personal Hygiene

Food workers should adhere to strict hygiene protocols:

- Keep fingernails short and clean to prevent breakage and contamination.

- Refrain from wearing jewelry such as rings, bracelets, or earrings that could fall into food.

- Use hair restraints like hairnets or caps to prevent hair from contaminating food.

- Wear clean uniforms and change them regularly.

- Wash hands thoroughly and frequently, especially after breaks and using the restroom.

- Cover all cuts and wounds with waterproof bandages and wear gloves over them.

These habits significantly reduce the risk of introducing physical contaminants into the food supply [1] .

2. Equipment Maintenance and Inspection

Regular inspection and maintenance of machinery and tools are essential for preventing physical hazards. Loose screws, broken parts, or worn-out equipment can introduce metal or plastic fragments into food. Establish a maintenance schedule, conduct routine checks, and immediately remove faulty equipment from use. Document all inspections and repairs to ensure accountability and traceability [1] .

3. Ingredient and Supply Chain Controls

Implementing thorough inspection protocols when receiving raw materials and ingredients is critical. Check for damaged packaging, foreign objects, or other signs of contamination. Work closely with trusted suppliers who maintain high safety standards, and require proper documentation for each batch of ingredients received. This approach helps identify risks early and prevents contaminated items from entering the food preparation area [1] .

4. Implementing a HACCP Plan

Hazard Analysis and Critical Control Points (HACCP) is an internationally recognized system for managing food safety risks. Food businesses should develop and implement a HACCP plan that addresses potential physical, chemical, and biological hazards at each stage of food processing. This plan should outline monitoring procedures, critical limits, corrective actions, and verification steps. Regular reviews ensure that the plan remains effective and up-to-date [1] .

Training and Continuous Improvement

Comprehensive training is essential for all food workers. Training should cover proper handling of chemicals, identification of hazards, use of PPE, emergency procedures, and safe food handling practices. Regular refresher courses keep employees informed about new hazards and updated protocols. Employers are responsible for providing accessible training materials and ensuring all staff understand and follow safety guidelines [2] .

Step-by-Step Guidance for Food Workers

- Always check chemical labels and Material Safety Data Sheets (MSDS) or Safety Data Sheets (SDS) before use. These documents provide essential information on safe handling, first aid, and emergency response [3] .

- Store chemicals in their designated area, separate from food and food contact surfaces.

- Use the correct cleaning agents and dilution rates as specified by manufacturers. Rinse all surfaces thoroughly after cleaning.

- Wear appropriate PPE whenever handling chemicals or cleaning equipment.

- Inspect all food, ingredients, and packaging for signs of physical contamination before use.

- Follow personal hygiene protocols strictly, including handwashing, hair restraints, and uniform policies.

- Regularly inspect and maintain equipment to prevent breakdowns that could result in contamination.

- If contamination is suspected or detected, isolate the product, report the incident, document actions taken, and follow disposal procedures.

- Participate in regular training and safety briefings to stay informed about best practices and new hazards.

Real-World Example: Responding to a Chemical Spill in a Commercial Kitchen

Consider a scenario where a cleaning agent is accidentally spilled near a food prep area. The food worker immediately identifies the chemical, cordons off the area, and removes any exposed food products. They report the incident to their supervisor, who logs the event and initiates corrective action. The contaminated products are safely disposed of according to local health regulations, and the area is thoroughly cleaned and sanitized. A review of procedures follows to prevent future incidents, and staff receive additional training on chemical handling protocols.

Challenges and Solutions

Common challenges in preventing chemical and physical hazards include lack of training, inadequate supervision, and time pressures leading to shortcuts. Solutions involve fostering a strong food safety culture, maintaining open communication, and investing in ongoing education for all staff members. Employers should also encourage reporting of near-misses and incidents to drive continuous improvement.

Source: numerade.com

Alternative Approaches

Some food service operations may adopt advanced technologies, such as metal detectors or X-ray machines, to identify physical hazards in products. Others may implement digital checklists and monitoring systems to ensure compliance with cleaning and storage protocols. While these technologies can enhance safety, they should complement, not replace, fundamental practices outlined above.

Accessing Resources and Further Guidance

Food workers and employers seeking additional guidance can:

- Contact local health departments for regulations and best practices specific to their region.

- Consult the U.S. Food and Drug Administration (FDA) or the U.S. Department of Agriculture (USDA) for food safety guidelines.

- Ask their employer for training materials, SDSs, or access to food safety courses.

- Search for “HACCP training programs” from accredited organizations for in-depth education.

Key Takeaways

Preventing chemical and physical hazards in food requires a multifaceted approach involving proper storage and use of chemicals, strict personal hygiene, equipment maintenance, thorough training, and a culture of safety. By following these comprehensive strategies, food workers can protect consumers and ensure compliance with food safety regulations.

References

- FoodDocs (2025). Chemical Hazards in Food: Examples & What Handlers Should Do.

- FSNS (2024). How to Help Prevent Physical Hazards in Food: A Guide for QC Teams.

- FoodReady.ai (2024). All You Need to Know About Chemical Hazards in Food.

- Vector Solutions (2025). Hazards in Food Processing Industry: A Guide.

- Cal/OSHA (n.d.). Hazard Communication Regulation.

MORE FROM eboxgo.com