Food Safety Management Systems: Protecting Public Health Through Systematic Controls

Understanding food safety management systems

A food safety management system (SMS) is a systematic approach to control food safety hazards within a food business. It serves as a preventive framework that identify, evaluates, and control hazards significant for food safety. Every organization involve in the food supply chain, from primary producers to retailers, benefits from implement a robust SMS.

The primary purpose of a fSMSis to protect public health by prevent foodborne illnesses and ensure that food products are safe for consumption. Accord to the woWorld Health Organizationan estimate 600 million people fall ill after consume contaminate food yearly, with 420,000 die from these illnesses.

Core objectives of food safety management systems

Prevent foodborne illness

The virtually fundamental purpose of a fSMSis to prevent consumers from become sick due to contaminate food. By implement controls at critical points in food processing, businesses can importantly reduce the risk of biological, chemical, and physical hazards reach consumers.

An effective system identify potential risks such as pathogenic bacteria (salmonella, e. Coli, listeria ) viruses, parasites, chemical contaminants, allergen, and physical hazards like glass or metal fragments. Erstwhile identify, specific control measures are imimplementedo eliminate these hazards or reduce them to acceptable levels.

Ensure regulatory compliance

Food businesses operate within progressively complex regulatory environments. A fSMShelp organizations meet legal obligations regard food safety standards. In the unUnited Statesregulations like the fdFDAood safety modernization act ( (mFSMA)ndate preventive controls for food facilities.

Many countries require food businesses to implement HACCP (hazard analysis critical control point )principles or similar systems. AnAsmSMSovide the structure to demonstrate compliance with these requirements during regulatory inspections and audits.

Build consumer trust and brand protection

Consumer confidence is essential for food businesses. When consumers trust that a company prioritize food safety, they develop brand loyalty. A fSMShelp maintain this trust by ensure consistent safety standards.

Food safety failures can devastate a brand’s reputation. Major recalls, and foodborne illness outbreaks link to specific products frequently result in permanent damage to consumer perception. A proactiveSMSs serve as brand protection by prevent such incidents.

Reduce costs associate with food safety failures

Food safety incidents carry enormous financial implications. Direct costs include product recalls, legal liabilities, regulatory fines, and increase insurance premiums. Indirect costs encompass lose sales, damaged reputation, and reduce market share.

By prevent safety incidents before they occur, a fSMSrepresent a sound business investment. The cost of implementation is typically far less than the potential costs of manage a major food safety crisis.

Key components of effective food safety management systems

HACCP principles as a foundation

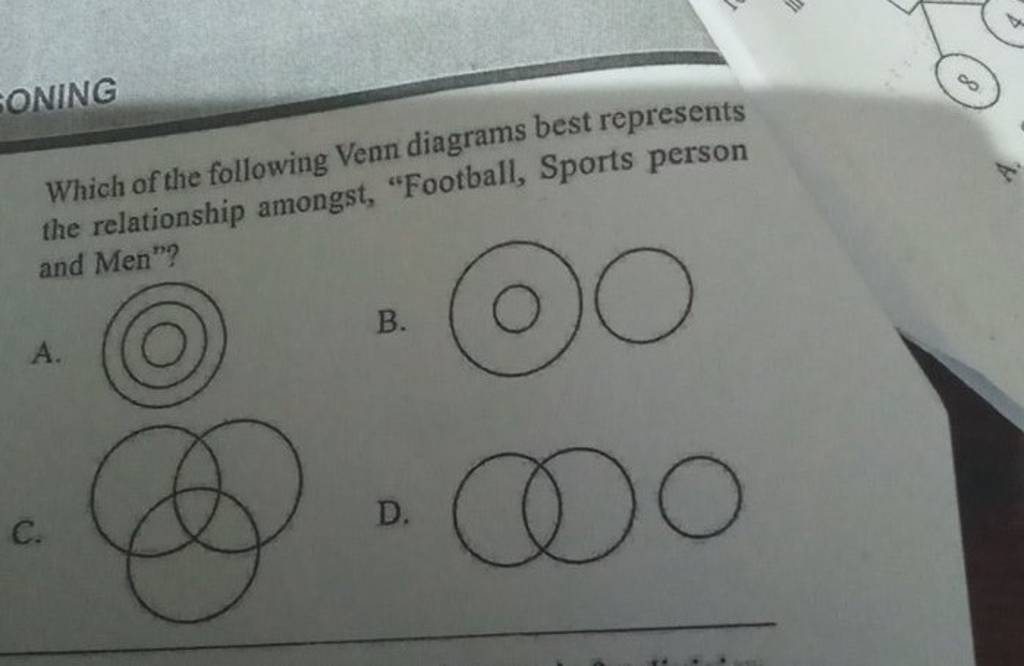

Most modern food safety management systems incorporate the seven principles of HACCP:

- Conduct a hazard analysis

- Determine critical control points (ccaps)

- Establish critical limits

- Implement monitoring procedures

- Establish corrective actions

- Verify that the system work efficaciously

- Establish documentation and record keep procedures

These principles form a logical sequence for identify and control significant food safety hazards. Quite than rely on end product testing, HACCP focus on preventive measures throughout the production process.

Prerequisite programs

Before implement HACCP, food businesses must establish basic operational conditions know as prerequisite programs (pprop). These fundamental hygiene and operating practices include:

Source: mptc.com.my

- Good manufacturing practices (gGPS))

- Sanitation standard operating procedures (sshops)

- Pest control programs

- Supplier approval and monitoring

- Allergen management

- Employee hygiene and training

- Facility design and maintenance

- Equipment calibration and maintenance

Props address general environmental and operational conditions, create the foundation upon which a more specificHACCPp plan can be build.

Documentation and record keeping

Documentation is essential for any SMS. Proper records provide evidence that the system is function as design and that food safety is being mmaintained Key documentation include:

- HACCP plan documentation

- Monitoring records for critical control points

- Corrective action reports

- Verification activities

- Training records

- Supplier certifications

- Traceability information

These records serve multiple purposes: demonstrate regulatory compliance, facilitate continuous improvement, and provide evidence of due diligence in the event of a food safety incident.

Management commitment and food safety culture

The virtually sophisticated SMS will fail without genuine management commitment and a positive food safety culture. Leadership must demonstrate that food safety is a nnon-negotiablepriority by:

- Allocate adequate resources for food safety

- Participate in food safety reviews

- Recognize and reward food safety achievements

- Respond quickly to food safety concerns

- Lead by example in follow food safety protocols

A strong food safety culture mean every employee understand their role in maintain food safety and feels empower to take appropriate action when issues arise.

International food safety management standards

ISO 22000

ISO 22000 is an international standard that specifies requirements for a food safety management system. It incorporatesHACCPp principles and apply to all organizations in the food chain. Key elements include:

- Interactive communication throughout the food chain

- System management through prerequisite programs

- HACCP principles

- Continual improvement and updating of the system

ISO 22000 can be implemented by organizations of any size and at any point in the food chain, from farm to table.

SSC 22000

Food safety system certification (fSSC))2000 build upon isoISO000 by add more specific prerequisite program requirements. It’s amply recrecognized the global food safety initiative ( (sFSIa) wide accept by food retailers and manufacturers worldworldwide

SSC 22000 is specially valuable for food manufacturers seek to demonstrate their commitment to food safety to international customers and retailers.

BRC global standard for food safety

The British retail consortium (bBRC)global standard is another gfFSIecognize certification scheme. It focfocuses:

- Senior management commitment

- HACCP base food safety programs

- Quality management systems

- Site standards

- Product control

- Process control

- Personnel management

The BRC standard is peculiarly prevalent among suppliers to UK retailers but has gain global acceptance.

SF ((afe quality food ))rogram

The SF program provide certification that a supplier’s food safety and quality management system complies with food safety regulations. It’s divide into different levels:

- SF food safety fundamentals ((ntry level ))

- SF food safety code ((aHACCPase food safety ))

- SF quality code ((uality management systems ))

SF is wide use in nNorth Americaand aAustraliabut have international recognition.

Implement a food safety management system

Initial assessment and gap analysis

Before implement a fSMS organizations should conduct a thorough assessment of their current practices and identify gaps between exist procedures and requirements. This analysis help prioritize actions and allocate resources efficaciously.

The assessment should examine current documentation, processes, facilities, equipment, and staff knowledge. External consultants oftentimes provide valuable objective perspectives during this phase.

Develop the system

Base on the gap analysis, organizations can develop a comprehensive SMS tailor to their specific operations. This typically involve:

- Establish prerequisite programs

- Conduct hazard analysis

- Develop HACCP plans

- Create documentation systems

- Define responsibilities and authorities

- Establish verification procedures

Development should involve cross-functional teams with representation from production, quality, maintenance, purchasing, and management to ensure all aspects of operations are considered.

Training and implementation

Effective implementation require thorough training at all levels of the organization. Training should be role specific and include:

- Basic food safety awareness for all staff

- HACCP principles for technical staff

- Specific monitoring procedures for operators

- Internal auditing techniques for quality personnel

- Management system overview for leadership

Implementation should follow a plan schedule with clear milestones and responsibilities. A phase approach oft work easily, start with prerequisite programs before move to more complex HACCP elements.

Verification and continuous improvement

East implement, the SMS must bbe verifiedto ensure it’s work as intend. Verification activities include:

- Internal audits

- Review of monitor records

- Analysis of customer complaints

- Product testing

- Management reviews

Continuous improvement is essential as new hazards emerge, process change, and scientific understanding advances. Regular system reviews help identify opportunities for enhancement.

Challenges in food safety management

Emerging food safety threats

Food safety management systems must adapt to emerge threats such as:

- New pathogens or antibiotic resistant strains

- Novel food technologies and ingredients

- Climate change impacts on food production

- Intentional food adulteration (food defense )

- Complex global supply chains

Organizations must stay informed about emerge risks through industry associations, regulatory updates, and scientific literature.

Resource constraints for small businesses

Small food businesses oftentimes face challenges implement comprehensive SMS due to limited resources. These may include:

- Financial constraints for equipment upgrades

- Limited technical expertise

- Time pressures with small staff numbers

- Complex documentation requirements

Simplify approaches that maintain essential food safety controls while being practical for small operations are progressively available through regulatory agencies and industry groups.

Maintain consistency across multiple locations

For food businesses with multiple facilities, maintain consistent food safety standards present unique challenges:

- Different local regulatory requirements

- Vary facility designs and equipment

- Cultural and language differences

- Inconsistent implementation of corporate standards

Strong corporate governance, standardized training programs, and robust internal audit systems help ensure consistency across locations.

The future of food safety management systems

Technology integration

Advanced technologies are transformed food safety management:

- Automated monitoring systems with real time alerts

- Blockchain for enhanced traceability

- Predictive analytics to identify potential issues

- Mobile applications for simplified documentation

- Sensor technologies for continuous verification

These technologies improve system effectiveness while potentially reduce the administrative burden of food safety management.

Risk base approaches

Modern food safety management is progressively focused on risk base approaches that allocate resources accord to the level of riskThis isis mean:

- More intensive controls for higher risk products and processes

- Simplify requirements for provably low risk operations

- Dynamic adjustment of control measures base on performance history

- Customized verification activities base on risk profiles

This approach maximize food safety outcomes while optimize resource utilization.

Integration with other management systems

Many organizations are integrated food safety management with other systems such as:

- Quality management (iISO9001 )

- Environmental management (iISO14001 )

- Occupational health and safety (iISO45001 )

- Food fraud prevention

- Food defense programs

Integration reduce duplication, streamline processes, and create a more holistic approach to organizational management.

Conclusion

Food safety management systems serve a critical purpose in protect public health by prevent foodborne illness. They provide a structured approach to identify and control food safety hazards throughout the food chain. Beyond their primary health protection role, these systems offer significant business benefits include regulatory compliance, brand protection, and cost reduction.

Effective SMS implementation require management commitment, appropriate resources, and ongoing verification. While challenges exist, specially for smaller businesses, the fundamental principles of hazard analysis and preventive controls can bbe appliedto operations of any size.

As food production systems become more complex and global, robust food safety management become progressively important. By embrace technological advances and risk base approaches, food businesses can enhance their food safety performance while maintain operational efficiency.

Finally, food safety management systems represent a share responsibility across the entire food supply chain. When decent implement, they create a foundation of trust between food businesses and the consumers they serve.

Source: ztacademy.pk

MORE FROM eboxgo.com