Food Defense: Protecting Food from Deliberate Tampering

Understanding food defense and deliberate tampering

Food defense refer to the protection of food products from intentional contamination or tamper with the intent to cause harm. Unlike food safety, which address accidental contamination, food defense specifically focus on deliberate acts of sabotage, terrorism, or tamper. These acts can occur anyplace along the food supply chain — from farm to table — and can have devastating consequences for public health, business operations, and consumer trust.

Deliberate food tampering can take many forms, include:

- Introduction of biological agents such as bacteria or viruses

- Addition of chemical contaminants like pesticides or clean agents

- Insertion of physical hazards such as glass, metal, or plastic

- Tamper with packaging to compromise product integrity

The motivations behind such acts vary from ideological terrorism to disgruntled employees, economic sabotage, or evening extortion attempts. Irrespective of motive, the protection of our food supply require robust, multi layered defense strategies.

Source: coursehero.com

Develop a comprehensive food defense plan

The foundation of effective food protection is an advantageously document, regularly update food defense plan. This plan should betailoredr to the specific vulnerabilities of your operation and include:

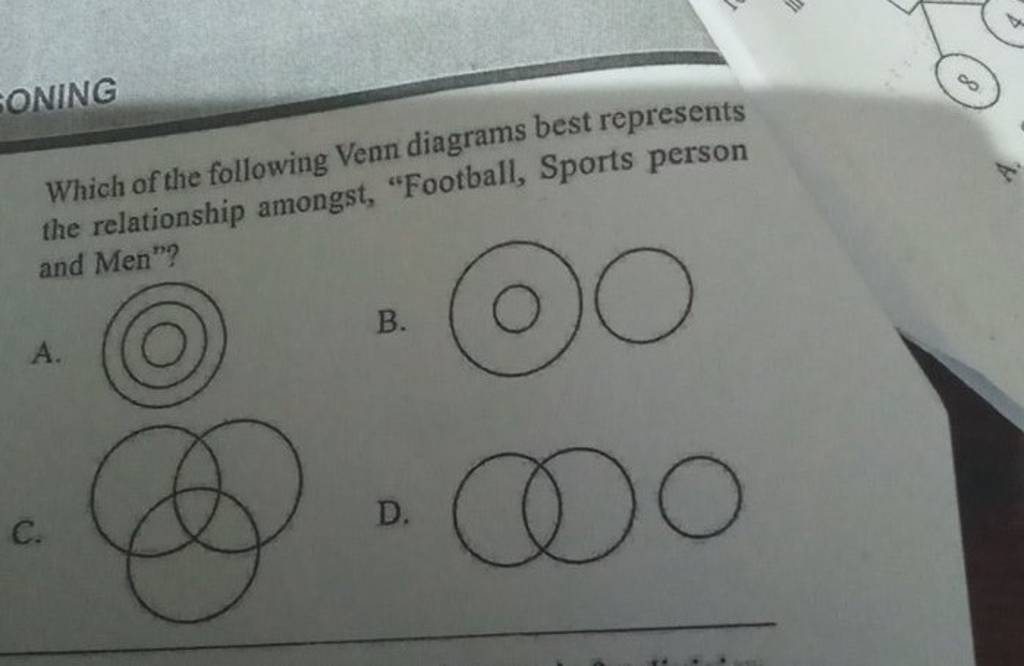

Vulnerability assessment

Begin with a thorough assessment of potential vulnerabilities throughout your operation. This process, sometimes call carver+shock analysis (criticality, accessibility, rrecoverability vulnerability, effect, recognizability, plus shock ) helps identify the virtually vulnerable points in your food production or handling system.

Key questions to consider during this assessment include:

- Which areas of your facility have limited supervision?

- Where are critical ingredients or finished products near expose?

- Which processes could virtually easy be compromise?

- What would be the public health impact of contamination at various points?

Mitigation strategies

Base on your vulnerability assessment, develop specific strategies to address each identify risk. These should be practical, implementable measures that importantly reduce the likelihood of successful tampering.

Emergency response procedures

Despite prevention efforts, it’s essential to have clear procedures for respond to suspect or confirm tamper incidents. These should include steps for product isolation, notification protocols, and recall procedures if necessary.

Physical security measures

Physical barriers and security systems form the first line of defense against deliberate tampering. Implement robust physical security measures importantly reduce the risk of unauthorized access to food products and ingredients.

Facility security

Secure the perimeter of your facility with appropriate fencing, gates, and control access points. All entry points should be secure when not in use, with particular attention to load docks, emergency exits, and utility access points.

Consider implement:

- Key card or biometric access systems for sensitive areas

- Clear designation of restricted zones with appropriate signage

- Regular inspection of perimeter security measures

- Adequate lighting throughout the facility, specially in vulnerable areas

Surveillance systems

Modern surveillance technology provide powerful tools for monitor facility activities and deter potential tampering:

- Strategically place security cameras cover critical production areas, storage facilities, and entry points

- Video monitoring systems with recording capabilities and appropriate retention periods

- Motion detection systems for off hours security

- Regular testing and maintenance of all surveillance equipment

Tamper evident packaging

One of the virtually effective ways to protect finished products is through tamper evident packaging. These solutions provide visible evidence if a package has been open or compromise after seal. Effective tamper evident features include:

- Shrink bands or seals that break upon opening

- Safety buttons on jar lids that pop when open

- Seal inner liners under caps

- Packaging that can not be resealed erstwhile open without obvious damage

For bulk ingredients, consider tamper evident seals on containers and requirement of seal verification before use.

Personnel security and management

People represent both the greatest vulnerability and the strongest defense against food tampering. Comprehensive personnel security measures are essential to protect food products.

Employee screening

The hiring process should include appropriate background checks for all employees, specially those with access to sensitive areas or processes. While the depth of screening may vary base on position, consider:

- Verification of employment history and references

- Criminal background checks where lawfully permissible

- Confirmation of require certifications or credentials

Training and awareness

All employees should receive training on food defense principles and their specific responsibilities. This training should include:

- Recognition of suspicious behavior or activities

- Proper procedures for report concerns

- Understand of access restrictions and the importance of compliance

- Awareness of the potential consequences of food tampering

Regular refresher training help maintain awareness and reinforce the importance of food defense measures.

Visitor and contractor management

Anyone who’s not a regular employee require special attention:

- Implement a visitor registration system with clear identification

- Require escorts for visitors in sensitive areas

- Establish specific protocols for contractors work on site

- Maintain detailed records of all visitor access

Operational procedures to prevent tampering

Day to day operations should incorporate specific procedures design to minimize tamper opportunities and maximize detection of suspicious activities.

Source: itv.com

Ingredient and material control

Careful management of ingredients and materials reduce tamper opportunities:

- Inspect all incoming materials for signs of tamper before acceptance

- Maintain chain of custody documentation for critical ingredients

- Store ingredients in secured areas with appropriate access controls

- Implement a first in, first out (fFIFO)inventory system with regular audits

Production line security

During production, products are peculiarly vulnerable to tampering. Protective measures include:

- Continuous supervision of production lines

- Clear protocols for line stoppages and restarts

- Physical barriers or enclosures for expose product areas

- Regular inspection of equipment for signs of tamper

Documentation and record keeping

Thorough documentation support food defense by create accountability and traceability:

- Maintain detailed production records with operator identification

- Document all access to restricted areas

- Record all maintenance activities on food processing equipment

- Implement a system for track product throughout the supply chain

Technological solutions for food defense

Advances in technology offer progressively sophisticated tools for protect food from deliberate tampering.

Detection systems

Various technologies can help detect potential contaminants:

- X-ray systems capable of detect foreign objects

- Metal detectors for identify metallic contaminants

- Vision systems that can spot package irregularities

- Chemical and biological detection systems for specific threats

Track and trace technology

Modern tracking systems provide unprecedented visibility into the movement of food products:

- RFID tagging for real time inventory tracking

- Blockchain technology for secure, immutable supply chain records

- QR codes that enable consumers to verify product authenticity

- GP track for transport vehicles

Cybersecurity for food defense

As food production become progressively automate, cybersecurity become a critical component of food defense:

- Secure control systems for automate production equipment

- Protection of inventory management and tracking systems

- Secure communication channels for sensitive information

- Regular security audits and updates

Supply chain considerations

Food defense extend beyond your immediate operation to encompass the entire supply chain.

Supplier verification

Develop a comprehensive supplier approval program that include:

- Assessment of supplier food defense programs

- On site audits where appropriate

- Clear specifications for delivery procedures

- Verification of security measures during transport

Transportation security

Products in transit are peculiarly vulnerable to tampering. Protective measures include:

- Seal transport containers with tamper evident features

- GP tracking of shipments

- Clear protocols for stops during transit

- Thorough inspection of vehicles before load

Collaborative approaches

Food defense is strengthened through industry collaboration:

- Participation in industry information share networks

- Coordination with local law enforcement and emergency responders

- Engagement with regulatory agencies on food defense initiatives

- Sharing of best practices within industry groups

Regulatory compliance and standards

Understand and comply with relevant regulations is essential for effective food defense.

FDA food defense requirements

In the United States, the food safety modernization act (fFSMA)include specific requirements for food defense, specially through the intentional adulteration rule. Key requirements include:

- Development of a food defense plan

- Vulnerability assessments

- Mitigation strategies

- Train for food defense personnel

International standards

Various international standards address food defense, include:

- Global food safety initiative (gFSI))enbenchmarkandards

- ISO 22000 food safety management systems

- Pas 96 guide to protect and defend food and drink

Certification programs

Consider participation in relevant certification programs:

- Customs trade partnership against terrorism (cct pat)

- Various FSI recognize certification schemes

- Industry specific security certification programs

Testing and validating food defense measures

Regular testing ensure that food defense measures remain effective.

Conduct drills and exercises

Periodic drills help identify weaknesses and prepare employees for potential incidents:

- Tabletop exercises simulate tamper scenarios

- Unannounced access control tests

- Mock recall exercises

- Emergency response drill

Auditing and assessment

Regular evaluation of food defense measures should include:

- Internal audits of food defense procedures

- Third party assessments where appropriate

- Gap analysis against regulatory requirements

- Review of incident reports and near misses

Continuous improvement

Food defense require ongoing refinement:

- Regular update to the food defense plan

- Incorporation of lessons learn from incidents and exercises

- Monitoring of emerge threats and technologies

- Benchmark against industry best practices

Conclusion: a layered approach to food defense

The virtually effective protection against deliberate food tampering come from implement multiple, overlap security measures. No single strategy or technology can provide complete protection. Alternatively, a comprehensive approach that combine physical security, personnel management, operational procedures, and technological solutions create a robust defense system.

By understand vulnerabilities, implement appropriate controls, and maintain vigilance, food businesses can importantly reduce the risk of deliberate tampering. This not but protect public health but besides preserve brand reputation and consumer trust — assets that are difficult to rebuild erstwhile compromise.

Food defense is not a one time project but an ongoing commitment that require regular assessment, testing, and improvement. As threats evolve, hence also must the strategies employ to counter them. Through diligence and comprehensive planning, the food industry can continue to provide products that consumers can trust.

MORE FROM eboxgo.com