Essential Steps Food Workers Must Take to Prevent Chemical Hazards in Food

Introduction: The Importance of Preventing Chemical Hazards in Food

Chemical hazards in food service environments pose a significant risk to consumer health and business reputation. These hazards-ranging from cleaning agents to pesticides and naturally occurring toxins-can enter food products through improper handling, storage, or accidental contamination. Food workers play a critical role in preventing chemical hazards from contaminating food by following strict protocols, maintaining high standards of hygiene, and responding swiftly to incidents. This article explores the comprehensive steps food workers must take to safeguard food from chemical hazards, providing practical guidance, real-world examples, and actionable steps for effective prevention.

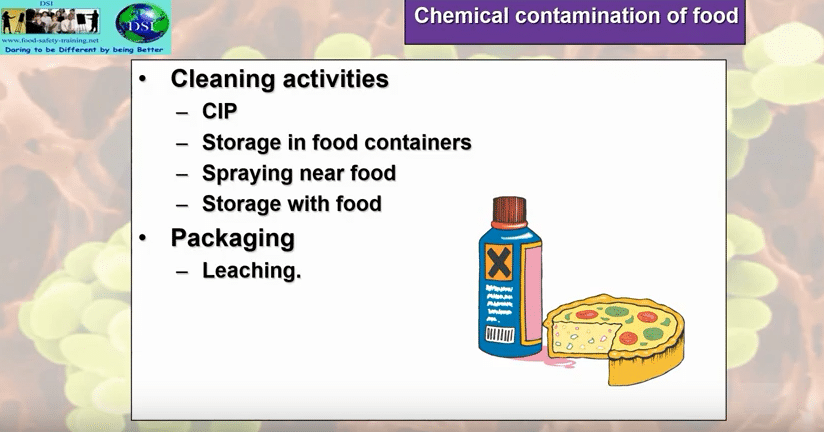

Understanding Chemical Hazards in Food

Chemical hazards are substances that, when present in food, can cause harm to consumers. They include cleaning chemicals, pesticides, heavy metals, and allergens. Chemical hazards may enter food through environmental exposure, cross-contamination, or improper use of substances within the facility. Recognizing the various sources and types of chemical hazards is essential for food workers to implement effective preventive measures. [5]

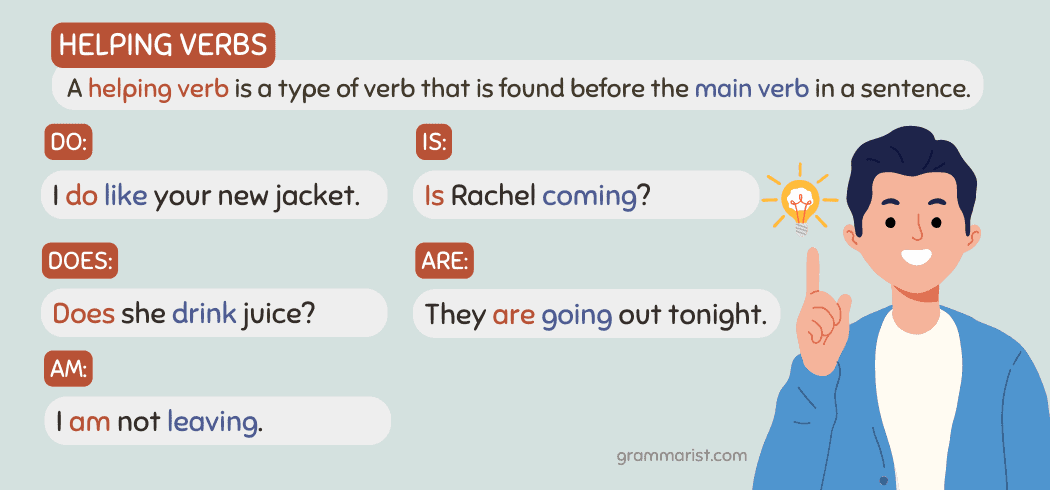

Personal Hygiene and Protective Equipment

Maintaining good personal hygiene is the first and most crucial step in preventing chemical contamination. Workers must:

- Wear appropriate personal protective equipment (PPE) such as gloves, aprons, and masks when handling chemicals or cleaning food-contact surfaces.

- Wash hands thoroughly with soap and water before and after handling any chemicals, and before touching food or food-contact surfaces.

- Avoid wearing jewelry or accessories that could trap chemical residues or contaminate food. [5]

For example, a food worker cleaning a slicer must remove gloves used for chemical handling, wash hands, and don new gloves before resuming food preparation. Failure to do so increases the risk of chemical cross-contamination.

Source: clickonenglish.blogspot.com

Proper Storage and Handling of Chemicals

Chemicals should always be stored in dedicated areas away from food, food packaging, and food-contact surfaces. Key steps include:

- Store chemicals in labeled, sealed containers in ventilated, corrosion-resistant cabinets.

- Keep chemicals away from heat sources, direct sunlight, water pipes, and food storage areas. [2]

- Use spill containment trays for liquids and ensure floors are resistant to chemical penetration.

- Never store food and chemicals together, even temporarily. This separation is critical to prevent accidental contamination.

Real-world example: In a busy restaurant, cleaning products must be stored in a locked cabinet far from refrigerated food storage-never under sinks where food is washed or prepped. Food workers should regularly check that containers are intact and report any swelling or leakage immediately. [2]

Strict Monitoring and Food Handling Procedures

Food workers must follow established protocols for monitoring and handling food to prevent chemical hazards:

- Use only approved chemicals for cleaning and sanitation, as indicated by facility policy and regulatory agencies.

- Follow manufacturer instructions and facility procedures for dilution, application, and disposal of chemicals.

- Sanitize food-contact surfaces with chemicals only when food is not present and allow surfaces to dry before use. [5]

- Conduct regular inspections and audits of chemical storage and usage logs.

For instance, a food worker disinfecting a prep table should ensure all food items are removed, apply the chemical as directed, rinse if required, and allow it to air dry before returning food to the area. Inadequate rinsing or premature use of the surface can leave harmful residues on food.

Training and Incident Response

Comprehensive training equips food workers with the knowledge to handle chemicals safely and react appropriately to potential hazards:

- Participate in regular food safety and chemical hazard training programs, including proper PPE use and emergency response.

- Receive instruction on reading chemical labels, understanding Safety Data Sheets (SDS), and hazard pictograms. [3]

- Know the steps to take if a chemical hazard is detected, such as isolating contaminated products, reporting the incident, documenting details, and implementing corrective actions. [4]

Example: If a spill occurs near a food preparation area, the worker must immediately cordon off the area, follow the facility’s spill response protocol using a spill kit, and notify supervisors. All affected products must be isolated and disposed of according to established guidelines. [4]

Continuous Improvement and Risk Assessment

Preventing chemical hazards requires ongoing evaluation and improvement of food safety protocols:

- Conduct regular risk assessments to identify potential sources of chemical contamination.

- Update procedures and training based on incident reports and regulatory changes.

- Work with suppliers to ensure ingredients and packaging materials meet safety standards.

- Encourage a culture of safety through toolbox talks, open communication, and employee recognition for safe practices. [3]

For example, after a chemical contamination incident, management should review the cause, update supplier requirements if needed, and revise storage procedures to prevent recurrence. [4]

Alternative Approaches and Solutions

While strict protocols are effective, facilities may consider alternative approaches to reduce risk:

Source: youtube.com

- Use less toxic or natural cleaning agents where appropriate and permitted by regulatory bodies.

- Implement automated dispensing systems for chemicals to minimize human error.

- Engage third-party auditors to review chemical control practices periodically.

Facilities can also explore new technologies, such as real-time monitoring sensors for chemical levels and compliance software for tracking incidents and corrective actions.

Practical Steps for Food Workers

To implement these prevention strategies, food workers should:

- Complete initial and recurring food safety and chemical handling training provided by your employer or relevant regulatory agency.

- Always check labels and SDS before using any chemical, and follow all instructions.

- Store chemicals separately from food, in designated, labeled cabinets.

- Wear proper PPE when handling chemicals, and wash hands before returning to food handling.

- Respond immediately to spills or suspected contamination by isolating the area, following your facility’s spill response plan, and notifying supervisors.

- Document all incidents and participate in follow-up risk assessments and corrective actions.

If your facility does not provide training or clear protocols, request guidance from management, or consult official agencies such as OSHA or your local health department. You can search for “food safety chemical hazard training” or contact your local regulatory authority for approved resources.

Potential Challenges and Solutions

Food workers may encounter challenges such as lack of training, unclear protocols, or limited resources. Solutions include:

- Advocating for regular training and clear written procedures.

- Requesting appropriate PPE and spill kits from management.

- Maintaining open communication with supervisors regarding safety concerns.

- Participating in safety committees or working groups to improve practices.

Key Takeaways

Preventing chemical hazards from contaminating food requires vigilance, training, and adherence to strict protocols. By implementing the steps outlined above-personal hygiene, proper storage, effective handling, timely incident response, and continuous improvement-food workers can protect public health, maintain regulatory compliance, and uphold the integrity of their workplace.

References

- [1] FoodDocs (2025). Chemical Hazards in Food: Examples & What Handlers Can Do to Prevent Them.

- [2] HSI (2024). How Are Food Manufacturing Workers Protected From Chemical Exposure?

- [3] Vector Solutions (2025). Hazards in Food Processing Industry: A Guide.

- [4] FoodReady (2024). All You Need to Know About Chemical Hazards in Food.

MORE FROM eboxgo.com