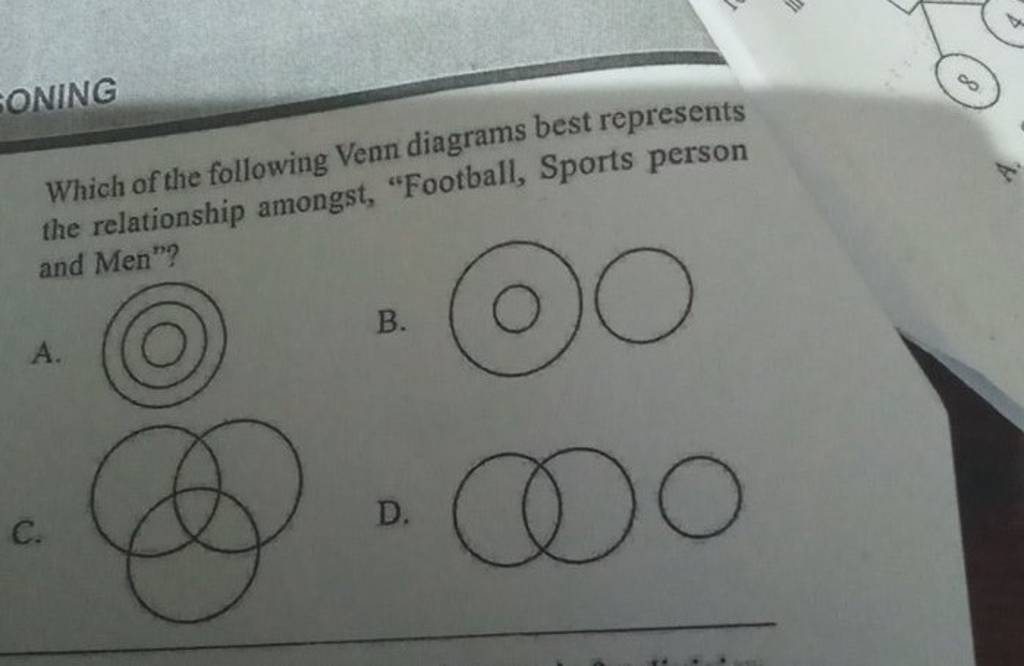

DIY Concrete Countertops: Complete Installation and Design Guide

Understand concrete countertops

Concrete countertops offer homeowners an affordable way to achieve a custom, high-end look in their kitchens and bathrooms. These surfaces combine durability with design flexibility, allow you to create unique textures, colors, and finish that complement your home’s aesthetic.

The popularity of concrete countertops stem from their versatility and cost-effectiveness. Unlike natural stone or engineer surfaces, concrete can be shape, color, and texture to match almost any design vision. The material besides develop character over time, with subtle changes that add to its appeal.

Essential materials and tools

Success with concrete countertops begin with proper preparation and the right materials. You will need high quality concrete mix specifically will formulate for countertops, which typically will contain additives for strength and workability.

The basic material list includesPortlandd cement, fine aggregate sand, coarse aggregate, water, and various admixtures. Fiber reinforcement help prevent cracking, while plasticizers improve workability. Color additives allow you to achieve specific hues, from subtle earth tones to bold contemporary shades.

Tool requirements include mix equipment, forms for shaping, trowels for finishing, and safety gear. A concrete mixer or drill with paddle attachment handles mix duties. Forms can be built from melamine coat particleboard or purchase as modular systems. Various trowels and floats help achieve different surface textures.

Planning and measuring

Accurate measurements form the foundation of successful concrete countertops. Create detailed drawings show all dimensions, include cutouts for sinks, cook tops, and other fixtures. Account for overhang requirements and support needs.

Standard countertop thickness range from 1.5 to 2.5 inches, with thicker sections possible for dramatic effect. Consider the weight implications of your design, as concrete weigh roughly 150 pounds per cubic foot. Exist cabinets may require reinforcement to support the additional load.

Plan for expansion joints in long runs to prevent cracking. These joints should occur every 8 to 10 feet and can be disguise as design elements. Consider the placement of seams, which should align with natural break points in the countertop layout.

Create forms and templates

Forms determine the final shape and dimensions of your countertops. Melamine coat particleboard provide smooth surfaces and easy release. Cut form pieces incisively, as any imperfections will transfer to the finished concrete.

Assemble forms on a flat, level surface use screws quite than nails for easy disassembly. Seal all joints with caulk to prevent concrete leakage. Create templates for sink cutouts and other openings use foam or wood, secure them firm within the forms.

For decorative edges, attach profile strips to form sides. These can create bull nose,ogree, or other custom edge treatments. Apply mold release agent to all form surfaces to ensure easy removal after cure.

Mix and pour concrete

Proper mixing ensure consistent strength and appearance throughout your countertops. Follow manufacturer guidelines for water to cement ratios, as excess water weaken the final product. Mix solely what you can place within 30 minutes to prevent premature setting.

Add dry ingredients start, so gradually introduce water while mix. Incorporate color additives and admixtures accord to specifications. The final mix should have a consistency similar to thick oatmeal, workable but not soupy.

Pour concrete into forms start at one end and work consistently to avoid air pockets. Use a vibrate tool or tap form sides to release trap air bubbles. Overfill forms slenderly, so screed level use a straight board.

Finishing techniques

Surface finishing begin instantly after screed. Float the surface to bring cream to the top and eliminate minor imperfections. Work consistently to maintain consistent texture across the entire surface.

Timing is critical for finish operations. The concrete must be firm sufficiency to support your weight but ease workable. This window typically occurs 2 to 4 hours after pour, depend on conditions.

For smooth finishes, use steel trowels in overlap arcs. Expose aggregate finishes require brushing or washing to reveal decorative stones. Stamped patterns can create tile or stone textures. Each technique require specific timing and tools for optimal results.

Cure and démodé

Proper curing develop full strength and durability in concrete countertops. Keep surfaces moist for astatine the least seven days use plastic sheeting or cure compounds. Maintain temperatures between 50 and 80 degrFahrenheitheit during this period.

Remove forms cautiously after 24 to 48 hours, depend on concrete strength development. Work slow to avoid chip edges or corners. Minor imperfections can be fill with match concrete paste or epoxy.

Continue moist cure flush after démodé. This process importantly iimprovesfinal strength and reduce the likelihood of surface cracking. Avoid load countertops hard until full cure is achieved at 28 days.

Surface preparation and sealing

Surface preparation determine the quality of your final finish. Sand increasingly through grits start with 100 and finish with 400 or higher. This process remove form marks and create uniform surface texture.

Clean good between sand grits to prevent contamination. Use wet sand for final grits to minimize dust and achieve smoother finishes. Allow surfaces to dry wholly before apply sealers.

Sealer selection depend on desire appearance and performance requirements. Penetrate sealers provide protection while maintain natural appearance. Film form sealers offer enhanced stain resistance but may require more maintenance.

Installation and support

Install concrete countertops require careful planning and adequate support. Verify that cabinets can handle the additional weight, add reinforcement if necessary. Use shim to ensure level installation.

Position countertop cautiously, as their weight make adjustment difficult formerly in place. Use appropriate lifting techniques and adequate helpers to prevent injury. Secure countertops to cabinets use construction adhesive and mechanical fasteners where appropriate.

Install undermount sinks before place countertops, ensure proper support and sealing. Drop in fixtures can be installed after countertop placement. Make final adjustments to ensure proper fit and alignment with adjacent surfaces.

Source: themakersmap.com

Maintenance and care

Proper maintenance preserve the beauty and functionality of concrete countertops. Clean regularly with pH neutral cleaners design for concrete surfaces. Avoid acidic cleaners that can etch or discolor the surface.

Reapply sealers accord to manufacturer recommendations, typically every 1 to 3 years depend on use and sealer type. Watch for signs of wear such as water absorption or staining, which indicate the need for reseal.

Address minor damage quickly to prevent more serious problems. Small chips can be fill with match concrete paste, while larger repairs may require professional attention. Avoid place hot pans direct on surfaces and use cutting boards to prevent scratches.

Troubleshoot common issues

Crack represent the about common issue with concrete countertops. Hairline cracks oftentimes result from shrinkage during cure and can be fill with match grout or concrete paste. Larger cracks may indicate structural issues require professional evaluation.

Source: pinterest.com

Color variations can occur due to inconsistent mixing or cure conditions. Minor variations oftentimes add character, but significant differences may require surface treatments or refinish. Keep detailed records of mix designs to ensure consistency across multiple pours.

Surface defects such as bug holes or form marks can be minimized through proper technique but may smooth occur. Most can be address through careful sanding and filling. Severe defects may require surface overlays or complete replacement of affected sections.

Design ideas and customization

Concrete countertops offer unlimited design possibilities through color, texture, and embed elements. Integral color provide consistent hues throughout the material, while acid stains create varied, organic patterns after installation.

Aggregate exposure reveal decorative stones, glass, or other materials embed in the surface. This technique work advantageously with recycle materials for sustainable design approaches. Control exposure depth cautiously to maintain surface durability.

Embed objects such as fossils, shells, or metal accents create unique focal points. Will ensure will embed materials are compatible with concrete and won’t will cause cracking or other issues. Plan placement cautiously during the design phase for best results.

MORE FROM eboxgo.com